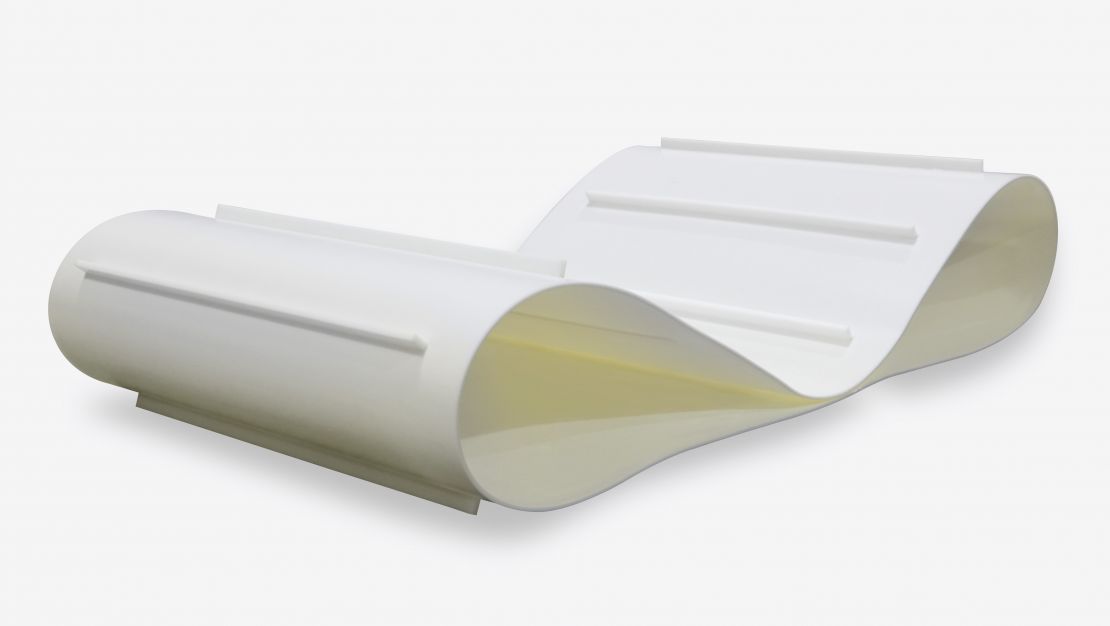

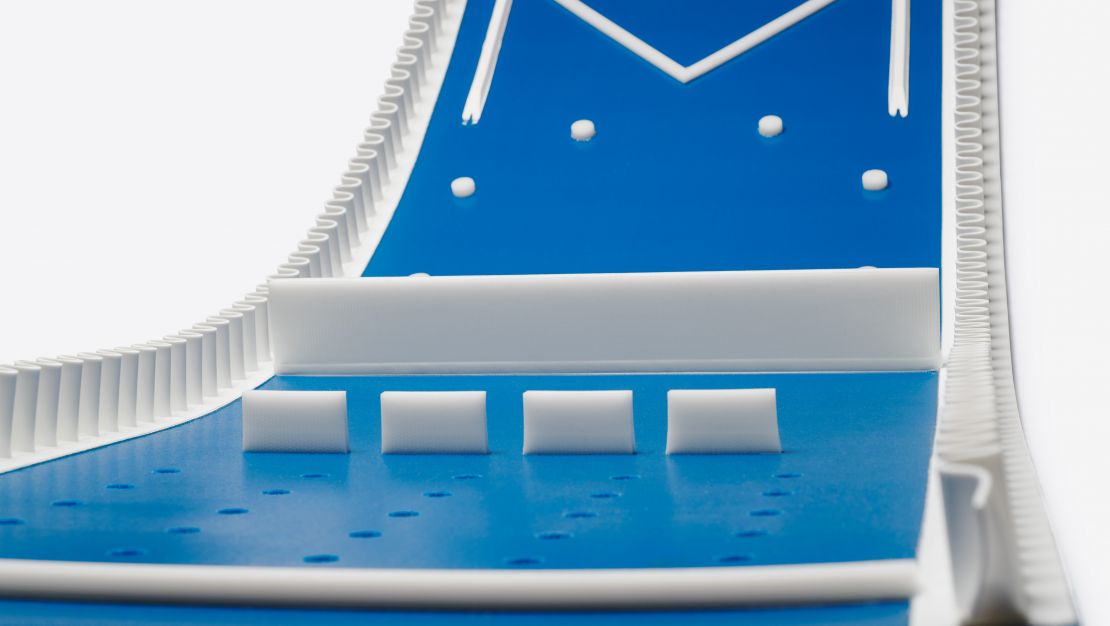

DISTRAM® conveyor belts

An effective alternative to classic conveyor belts

Composed of high-quality fibres and RESIP®, DISTRAM® belts benefit from exceptional performance and are used for applications where the usual materials (rubber, PVC, TPU) show their limitations. Manufacture by continuous casting and not gluing of a coating means that DISTRAM® belts have an increased service life, thus reducing your maintenance costs and operating losses.

They are available in white or blue, with a 1 or 2 ply carcasses and different stiffnesses and thicknesses for flat or trough use.

Excellent abrasion resistance

Excellent resistance to cutting, tearing and punching

Very good resistance to fats, oils, hydrocarbons, acids and bases. Good resistance to alcohol and ethers depending on concentration

Wide permissible temperature range

Your customised DISTRAM® conveyor belts

Custom-made, we fit guides, sidewalls, cleats, etc. according to your needs and specifications. We can supply them as a continuous belt or “prepared for auger”, to be closed by you, depending on the type of joint needed: saw-tooth, bevel, staples or other.

DISTRAM® belts in various sectors

Thanks to their uncompromising robustness, our DISTRAM® belts are particularly appreciated for heavy-duty applications, such as grinding, the transport of sharp waste, metal recycling, the wood industry, etc. but also in the agri-food sector, since they meet current standards.